A complete industrial automation solution

Smart Factory solution helps you keep track of production on your factory floor and measure productionperformance. Smart Factory solution makes it possible for you to collate and analyze data across machines to make your processes faster and more efficient.

PREMIUM PARTNER

Why Smart Factory

- On-the-go access with cloud based system

- Optimized efficiency

- Measurable cost reduction

- Guaranteed productivity gains

- Minimized downtime and predictive alerts

- Presents new business opportunities

Pain areas

- Legacy industrial control systems that are prone to cyber threats

- Lack of real-time data and disparate data systems

- Keeping abreast of regulations and managing compliance

- Product development and innovation

- Balancing maintenance with throughput

- Ensure customer satisfactions

Benefits

Verticals

- Electronic and Electrical Equipment Industry

- Fabricated Metal Industry

- Food and Kindred Industry

- Industrial and Commercial Machinery Industry

- Measuring, Analyzing and Controlling Instrument Industry

- Petroleum Refining and Related Industry

- Primary Metal Industry

- Rubber and Miscellaneous Plastic Industry

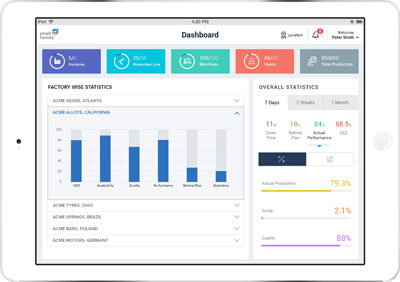

KPIs

- Availability

- Quality

- Down Time

- Behind Plan

- Actual Performance

- OEE

- Machine Down Time

- Machine In Use

- Machine Idle Time

Features

Interactive dashboard

- Large-scale, multi-site production line monitoring using an interactive dashboard

- Users can monitor overall statistics and KPI graph for each factory

- A quick glance at the overall performance of each factory and gain operational visibility

Predictive Analytics

- Data stream processing for predictive maintenance analysis

- Avoid sudden breakdowns and take a condition-based maintenance approach

- Monitor important KPIs based on predictive modeling

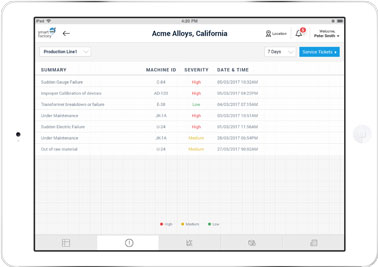

Ticketing Systems for Issue Tracking

- Identify poor machine performance and generate service tickets

- Track the status of all tickets from a single view

- Better interdepartmental communications

Machine Telemetry Data

- Displays graph of telemetry data of the sensors (associated with machines across the production line)

- Get a notification when the threshold limit is crossed to take quick decisions

Performance Anomaly Diagnosis

- Users can monitor machines’ current as well as past status and health via sensor data

- Monitor a graph for machine performance (%) with downtime, in use, idle parameters

- Receive factory/floor/production line related notifications to immediately act and resolve the issues and avoid unnecessary delays

Du ønsker at udnytte fordelene i cloud. Vi hjælper dig med at realisere dem.

Kontakt os via kontaktformularen, på telefon +45 8882 6290 eller

e-mail service@timengo.com.