Ensure the safety of your factory and workers by avoiding hazardous incidents

Industrial processes like burning fossil fuels, chemical processing, mixing and drilling into tunnels and mines, metal casting, coatings, oil paintings emit a large amount of toxic gases like CO, CO2, CH4, SO2, VOCs, NH3, LPG, H2 and many other which create the worst impacts on work environment. The flammable hazards and human health hazards are the primary concerns if these gases have been breathed in or not controlled in the proportion.

Industries like underground mining/tunnels, petrochemicals, metal refining, oil & gas, recyclable, fertilizers and refractories are considered dangerous and they ought to manage safety compliances. The accidents due to gas leakages are common there. With an average person spending around 90% of their time indoors, the effects of indoor air quality are more injurious compared to outdoor air pollution. That’s why it is important to monitor and control gas emissions from these industrial units.

Our IoT-based Smart Air Quality Monitoring Solution allows you to assess toxic and flammable gas proportions along with the concentration of air pollutants all year round. You can also automate this journey with our smart solution.

PREMIUM PARTNER

Benefits

Verticals

- Electronic and Electrical Equipment Industry

- Fabricated Metal Industry

- Food and Kindred Industry

- Industrial and Commercial Machinery Industry

- Measuring, Analyzing and Controlling Instrument Industry

- Petroleum Refining and Related Industry

- Primary Metal Industry

- Rubber and Miscellaneous Plastic Industry

KPIs

- Availability

- Quality

- Down Time

- Behind Plan

- Actual Performance

- OEE

- Machine Down Time

- Machine In Use

- Machine Idle Time

Features

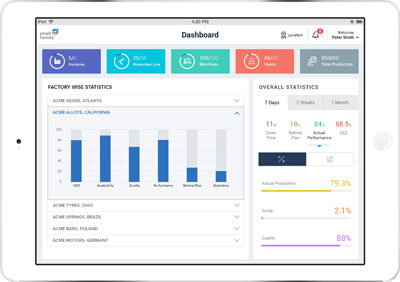

Interactive dashboard

- Large-scale, multi-site production line monitoring using an interactive dashboard

- Users can monitor overall statistics and KPI graph for each factory

- A quick glance at the overall performance of each factory and gain operational visibility

Predictive Analytics

- Data stream processing for predictive maintenance analysis

- Avoid sudden breakdowns and take a condition-based maintenance approach

- Monitor important KPIs based on predictive modeling

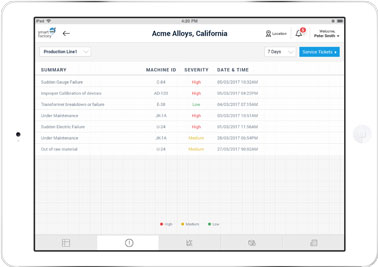

Ticketing Systems for Issue Tracking

- Identify poor machine performance and generate service tickets

- Track the status of all tickets from a single view

- Better interdepartmental communications

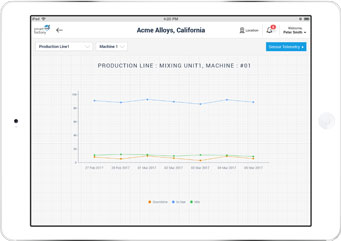

Machine Telemetry Data

- Displays graph of telemetry data of the sensors (associated with machines across the production line)

- Get a notification when the threshold limit is crossed to take quick decisions

Performance Anomaly Diagnosis

- Users can monitor machines’ current as well as past status and health via sensor data

- Monitor a graph for machine performance (%) with downtime, in use, idle parameters

- Receive factory/floor/production line related notifications to immediately act and resolve the issues and avoid unnecessary delays

Du ønsker at udnytte fordelene i cloud. Vi hjælper dig med at realisere dem.

Kontakt os via kontaktformularen, på telefon +45 8882 6290 eller

e-mail service@timengo.com.